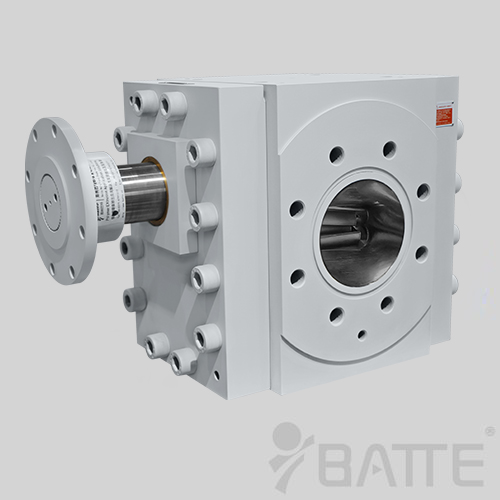

Wear-resistant melt pump is an important equipment in polyester plant. The polyester wear-resistant melt pump produced by Zhengzhou batte mostly uses mechanical seal as filler seal. When the mechanical seal is used in the melt pump, because the temperature of the melt is too high, the spring and the tine ring are easy to deform and the impurities in the melt exist, the life of the mechanical seal is generally shortened by about half a year, and the cost is high. Packing seals are characterized by rapid wear and tear of fillers and bushes, as well as the need for atmospheric compaction of fillers and heavy replacement. Therefore, mechanical seals and packing seals will result in increased maintenance workload and frequent replacement. Dry polyester production is continuous production.

The increase of maintenance volume brings great difficulties to safety production. The screw seal of wear-resistant melt pump is reformed, and good results have been achieved through theoretical and practical experiments and practices.